Midea High Efficiency Centrifugal Chiller 1800rt Heatexchanging Technology Water Cool Chiller China

Midea CAC IntroductionMidea Product Portfolio Products Show Product Details Magnetic centrifugal chiller compressor is a

Description

Basic Info.

| Model NO. | Centrifugal Chiller-5 |

| Compressor Number | 1 |

| Noise Level | Low |

| Application Fields | Electroplating |

| Certification | RoHS, ISO, CE, CCC |

| Condition | New |

| Iplv | 10.08-10.53W/W |

| Cop | 6.398-6.467W/W |

| Brand | Midea |

| Power Supply | 380V-3pH-50Hz |

| Cooling Capacity | 597.7-900.0kw |

| Power Input | 93.40-489.3kw |

| Name | Water Cooled Magnetic Centrifugal Chiller |

| Transport Package | Pallet |

| Specification | 4000*2500*2400 |

| Trademark | Midea |

| Origin | China |

| HS Code | 8415 |

| Production Capacity | 5000piece/Year |

Product Description

Midea CAC IntroductionMidea Product PortfolioProducts Show

Product Details

Magnetic centrifugal chiller compressor is a miniaturized, highly innovative compressor withmagnetic bearing, VFD and permanent magneticsynchronous motor technologies. It realizedoil-free, effective and safe operation. Magnetic bearing guarantees total levitating of the rotorduring operation. No contact between the bearing and rotor, no fricition and structural vibtation.

| Power supply | 380V-3Ph-50Hz | |

| Cooling Capacity | 170RT-900RT | |

| Power input | 93.40kw-489.3kw | |

| COP | 6.398-6.200w/w | |

| IPLV | 10.08-11.06w/w | |

Product Advantages

1.AHRI Certified

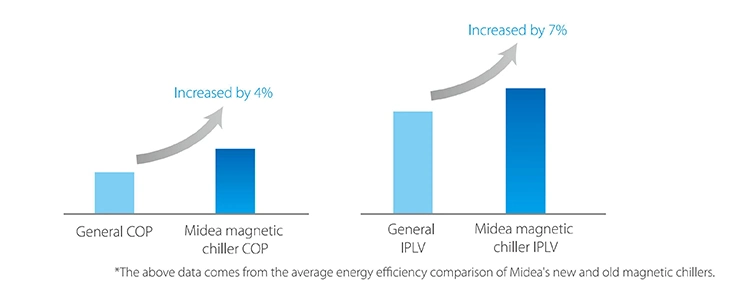

2.Oil-free and High EfficiencyMidea magnetic bearing centifugal cillr boasts magnetic bearing technology, aerodynamictechnology, a permanent magnet synchronous motor, and full flling film evaporation technology.It combines Midea's unique horizontally back-to-back two-stage compression structure withhigher energy eficlency as compared with the traditional magnetic bearling centifugal chiller,improving the flHoad energy ffciency by 4%6*, and improving the part-load energy efrciency by7%6*.

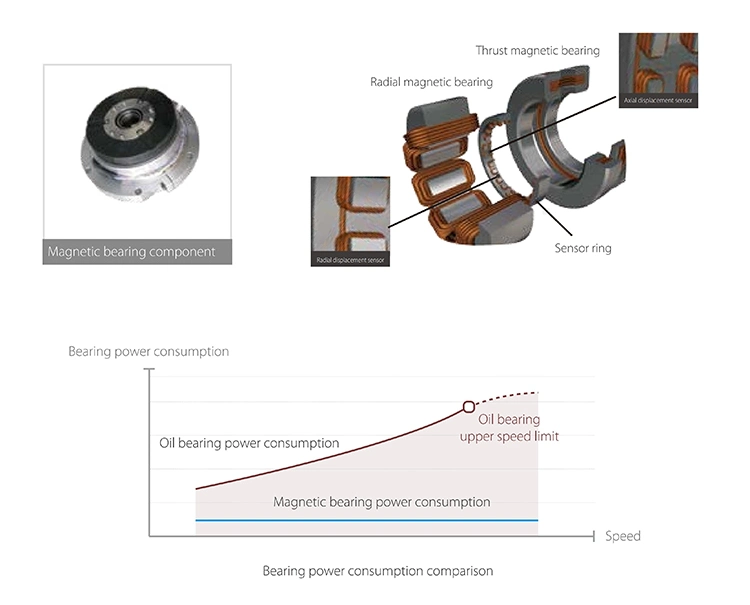

3.Magnetic bearing technologyIndutria-Hevel magnetic bearing assembly including the radial magnetic bearing,thrustmagnetic bearing and position sensor,and featuring low power consumption,high bearingcapaclty and high rlbility.Power consumption less than 0.4kW,only 2%to 10%of that of conventional oll bearings.Breaks through the upper speed limits of conventional oill bearings,signifcantly reducing powerconsumption of the bearing at high speed:the higher the speed,the more energy eficient themagnetic bearing is compared to the oil bearing.

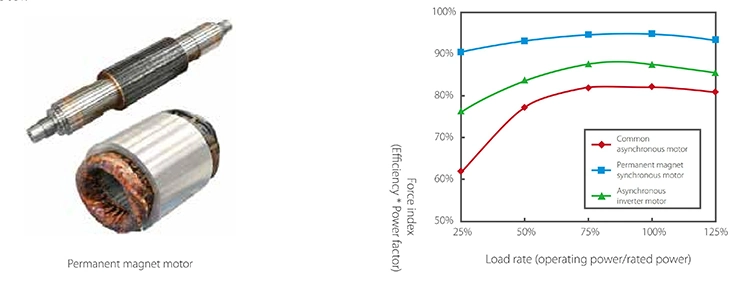

5.Permanent magnet synchronous motor technologyMotor efciency exceeds 96%in the full operating range,with the highest efciency of up to 97%.The space vector pulse width modulation(SVPWM)technology is used for speed regulationand driving.Accurate and effcient operation is achieved according to changes in the operatingconditions,the startup current Is small,the operating curent is low,and the operating electricitycharge and distribution cost of the whole lfe cycle are low.The realtime monitoring system of stator temperature and rotor shaft elongation achieveprecise,highly-elablel colingof the motar.

Projects Show

About Beijing Midea Overseas

Our Company Advantages

Our Contact

Send now